How Large Format Printers Bring Big Ideas to Life

How do large format printers work is a common question for Philadelphia business owners who need to make a big visual impact. These powerful machines use advanced inkjet technology to create oversized prints that grab attention and drive results.

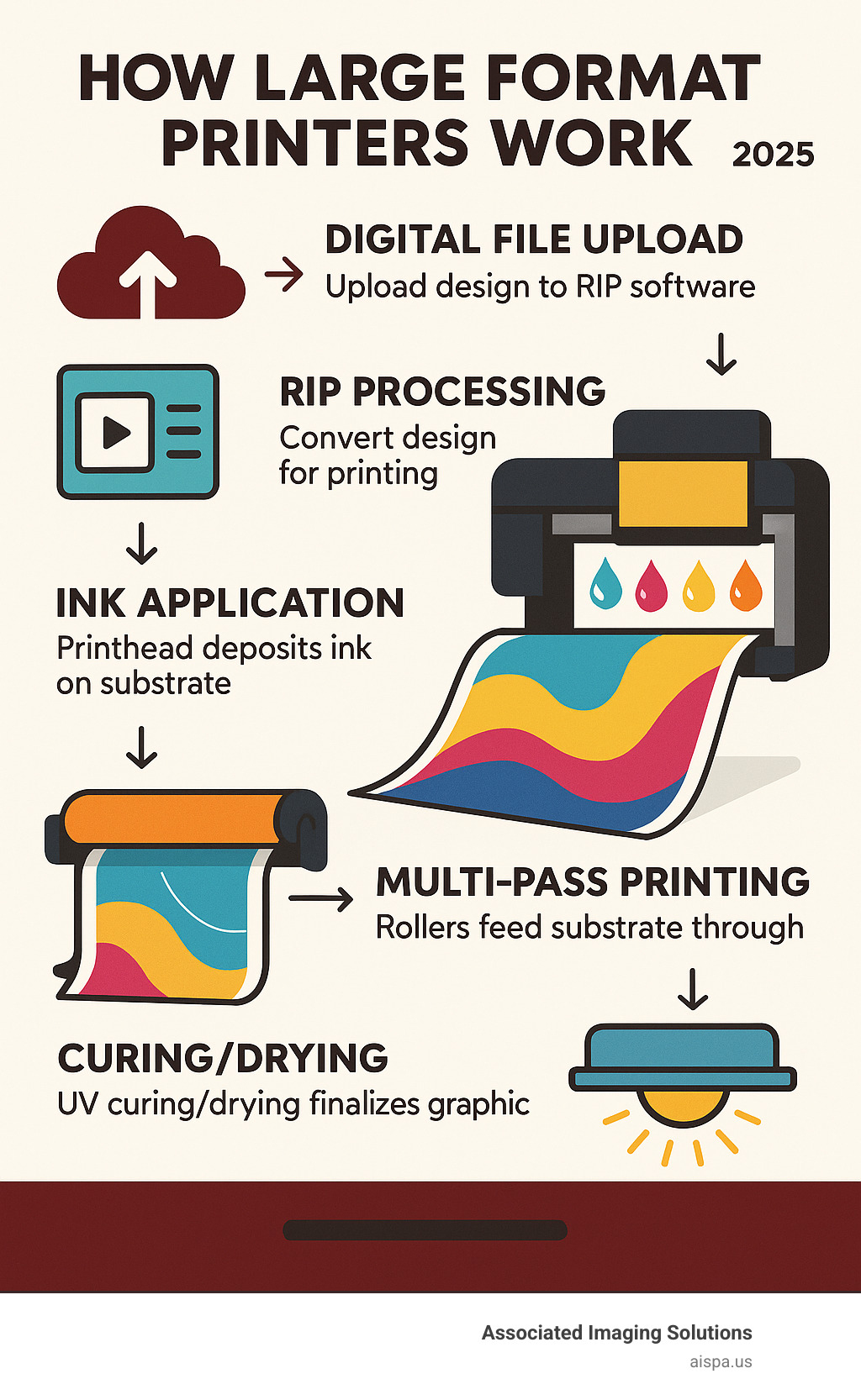

Here’s how large format printers work in simple terms:

- Digital Processing – Your design file is converted by RIP software into printable data.

- Ink Application – Printheads with thousands of nozzles spray tiny ink droplets onto the material.

- Precise Movement – The printhead moves across the substrate while rollers feed the material through.

- Layer Building – Multiple passes create the full image with up to 2,000 drops per centimeter.

- Curing/Drying – UV lights or heaters solidify the ink for immediate handling.

Large format printing has transformed how businesses communicate visually. From vehicle wraps on Philadelphia streets to billboards along I-95, these prints are everywhere. The technology can handle materials up to 5 meters wide, printing on everything from vinyl banners to metal signage.

The global large format printing market is expected to grow from $8 billion to $10.4 billion by 2028, showing how essential this technology has become for modern marketing.

Understanding how these machines work helps you make better decisions for printing architectural blueprints, trade show displays, or storefront graphics. The process combines precision engineering with creative possibilities unavailable with traditional printing methods.

What is Large Format Printing and How Does It Differ?

Think of large format printing as the superhero version of regular printing. Unlike office printers for everyday documents, large format printers create prints that make people stop and stare. These prints can span 18 to 100+ inches wide, with some machines handling materials over 5 meters wide.

The key difference isn’t just size, but what they print on. While office printers use paper, large format printers work with a variety of substrates (the material being printed on). They handle vinyl for vehicle wraps, canvas for art, metal for signage, and fabric for backdrops, offering creative possibilities paper can’t match.

You might hear terms like wide format printing or grand format printing. They’re all in the same family. Wide format typically refers to printers handling media from 18 to 100 inches wide. Grand format takes it up a notch, handling materials over 100 inches wide for massive billboards.

Impressively, these machines don’t sacrifice quality for size. Many can achieve up to 2400 x 1200 dpi resolution, so giant prints look crisp and professional up close. For more details, check out our guide on Wide Format Printers.

The production scale is another key difference. Large format printers are built for continuous commercial work, producing hundreds of square feet of material daily, far beyond a standard office printer’s capacity. To understand more, read about Production Printers vs. Office Printers.

Key Differences from Standard Printers

Here’s a breakdown of what sets large format printers apart from standard office machines.

| Feature | Standard Office Printers | Large Format Printers |

|---|---|---|

| Size | Compact, desktop or small floor models | Industrial-sized, often requiring dedicated space |

| Media | Paper (letter, legal, tabloid), envelopes | Rolls of vinyl, fabric, canvas, wood, metal, rigid boards |

| Ink | Toner (laser) or water-based dye/pigment (inkjet) | Specialized inks: solvent, eco-solvent, UV-curable, latex |

| Speed | Measured in pages per minute (PPM) | Measured in square feet per hour (e.g., 1,140 sq ft/hr) |

| Application | Documents, reports, small flyers, everyday office needs | Billboards, banners, vehicle wraps, wall murals, signage |

Desktop printing limitations are clear when you need to create something that demands attention, like a storefront banner. A standard printer would require taping dozens of sheets together, resulting in an unprofessional look.

Large format printers are built for commercial applications where visual impact is key. They use durable, specialized inks and are mechanically designed for heavy, continuous operation.

Whether you need small office solutions or industrial-scale printing capabilities, we’ve got you covered. Explore our complete range of Copiers & Printers to find the perfect fit for your business needs.

How Do Large Format Printers Work? The Core Technology

The core of how large format printers work is sophisticated inkjet technology, scaled up to handle oversized materials. It’s a precise process that turns a digital file into a massive masterpiece.

Your design file first goes through a Raster Image Processor (RIP). This crucial software acts as a translator, converting your design into a dot-by-dot map that tells the printheads where to place each ink droplet.

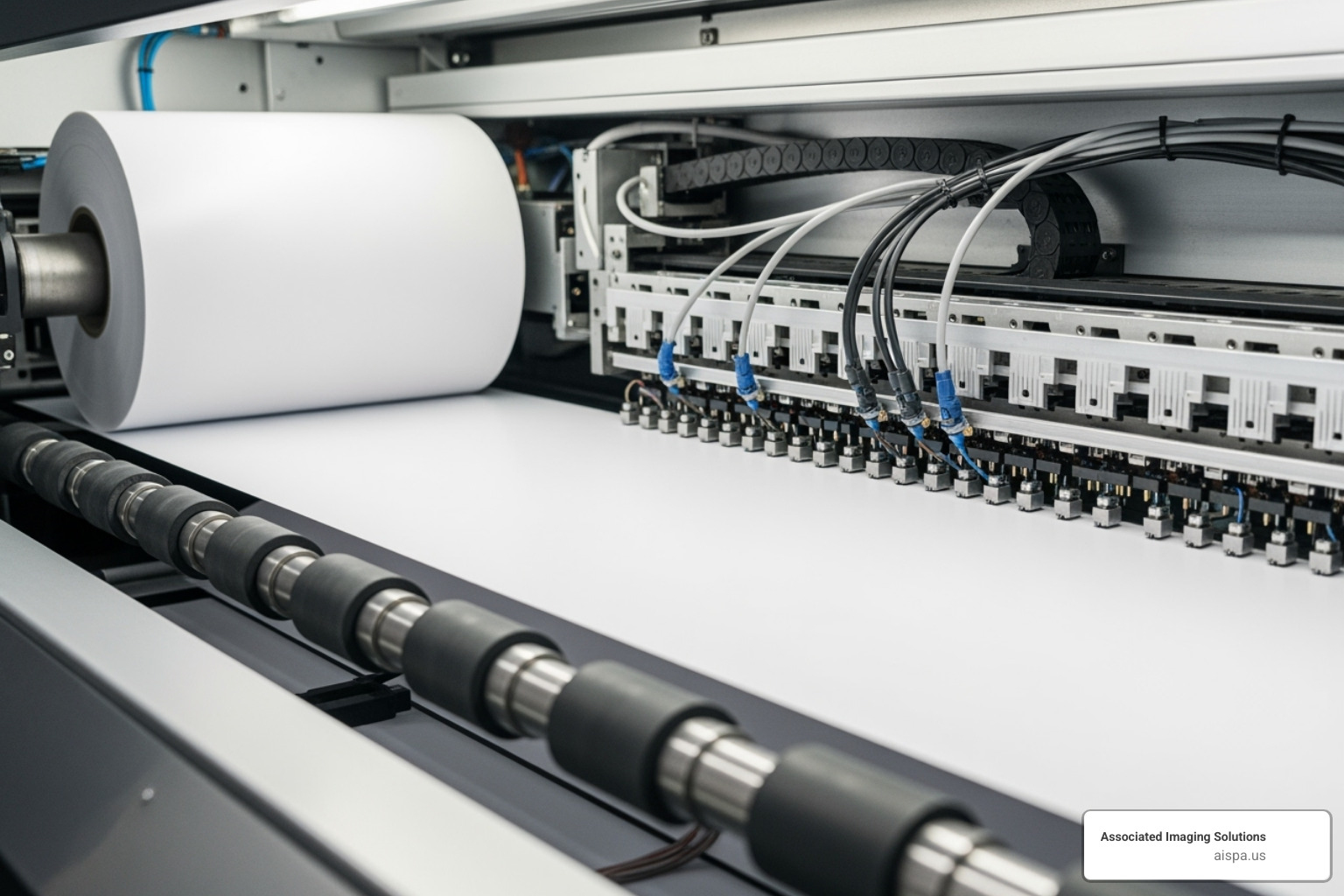

After translation, the mechanical movement begins. A printhead carriage glides across the printing surface while precision rollers feed flexible materials like vinyl. For rigid materials like wood or metal, flatbed printers move the substrate on a special table beneath the printheads.

The ink deposition process is where the image is created. The printhead sprays microscopic ink droplets with incredible precision—up to 2,000 drops per centimeter—building the image layer by layer. This process transforms your digital file into a tangible, large-scale print.

The Main Components and How They Work

Understanding these components helps explain exactly how large format printers work their magic.

- Printheads: These components house up to 2,050 nozzles per printhead. Each nozzle is a microscopic spray gun controlled by electrical signals, determining where each ink droplet lands. This density allows for fast, detailed printing.

- Ink Delivery System: Unlike desktop printers, these machines use large ink reservoirs (cartridges or bulk tanks) for long print jobs. The inks are specially formulated for durability and bonding with various materials. For a deeper understanding of this fundamental technology, check out our guide on What is an Inkjet Printer?.

- Media Feed System: For flexible materials, roller systems smoothly pull vinyl or fabric through the machine. On flatbed printers, vacuum systems hold rigid substrates flat as the printheads move overhead.

- Curing System: Powerful UV lamps or integrated heaters instantly cure the ink (UV-curable, latex, or solvent). This rapid curing allows for immediate handling and installation.

The Inkjet Printing Technique Explained

The core of large format printing is droplet technology, where microscopic ink droplets are placed with perfect accuracy.

Printers use two main methods. Piezoelectric inkjet uses ceramic elements that flex with electricity to push ink out, offering precise control and ink versatility, making it ideal for professional use. Thermal inkjet heats the ink to create a vapor bubble that ejects the droplet, a less expensive but common method.

Many large format printers expand on the basic CMYK color model, adding light cyan, light magenta, white ink, and clear varnish. This expanded palette creates smoother color transitions and allows printing on dark or transparent materials. To understand how this compares to other printing methods, take a look at our Inkjet vs. Laser Printer comparison.

The image is built through multiple passes, where the printhead layers ink to create the final image. This method, combined with resolutions up to 2400 x 1200 dpi, ensures crisp detail even on large prints.

Ink formulation is key. Solvent and eco-solvent inks are durable for outdoor use. UV-curable inks dry instantly on almost any material. Latex inks are an eco-friendly, vibrant option. The right ink determines the print’s longevity and application.

A World of Possibilities: Materials and Applications

The versatility of how large format printers work with different materials is remarkable. They don’t just print on paper; they can transform almost any surface into a vibrant canvas, making them a game-changer for businesses seeking high impact. Substrates fall into two main categories: flexible materials in rolls and rigid materials for flatbed systems. This adaptability allows for everything from weather-resistant banners to sleek metal signs.

The marketing and advertising impact is revolutionary. Large format prints grab attention in ways standard printing cannot. Vehicle wraps and massive trade show displays help businesses cut through the noise and connect with their audience.

At Associated Imaging Solutions, we understand that choosing the right printer and materials can be overwhelming. Our team provides personalized guidance to find the perfect solution for your needs. If you’re considering this capability, explore our range of Commercial Printers for Sale.

What Materials Can Be Printed On?

The range of materials is impressive, each offering unique advantages:

- Vinyl: This durable, weather-resistant material is perfect for outdoor banners, vehicle wraps, and window graphics. It comes in self-adhesive, perforated, and transparent forms.

- Fabric and Textiles: Polyester and other textiles create lightweight, professional signage for indoor displays and trade show backdrops. The dye-sublimation process embeds colors into the fibers for vibrant, durable prints.

- Canvas: Provides a classic, artistic textured finish perfect for art reproductions, wall murals, and upscale decor.

- Wood and Metal: Printers can print directly onto these materials, creating custom signs and architectural elements for designers and architects.

- PVC and Foam Board: These are cost-effective, lightweight, and rigid solutions for indoor signage, POP displays, and exhibition graphics.

- Specialized Materials: These include waterproof corrugated plastic for temporary outdoor signs and durable Dibond aluminum for long-term use. Printing on glass and acrylic creates stunning, modern results.

Common Uses Across Industries

- Marketing and Advertising: Massive billboards, vehicle wraps that act as mobile ads, and point-of-purchase displays grab attention and influence purchasing decisions.

- Events and Exhibitions: Trade show booths, stage backdrops, and floor graphics create immersive experiences, help exhibitors stand out, and guide attendees.

- Architecture and Engineering: They produce precise, durable blueprints, construction plans, and architectural renderings that remain clear on busy job sites.

- Interior Design: Custom wall murals and decorative wallpapers can transform a space. Businesses use large prints on canvas or fabric to create unique, branded environments.

- Retail and Point-of-Sale: Window graphics, in-store banners, and floor decals announce promotions and guide customers, boosting brand presence and turning browsers into buyers.

From Screen to Print: The Large Format Workflow

Creating a stunning large format print is a multi-step process that ensures your creative vision translates perfectly into a physical product. The workflow includes design, pre-press, printing, and finishing.

- Design: This phase requires more than just scaling up. Designers must consider viewing distance, which affects font sizes and image resolution.

- Pre-press: The file is inspected, colors are verified, and RIP (Raster Image Processor) software translates the design for the printer. The printer driver acts as the communication bridge between the computer and the printer. Understanding What is a Printer Driver? helps explain this essential component.

- Printing: During this stage, precision printheads deposit millions of ink droplets. Many modern printers have built-in quality control systems that use cameras to monitor nozzles and auto-adjust for accuracy.

- Finishing: This final stage turns the raw print into a final product through lamination, cutting, or mounting, which is crucial for impact and longevity.

How to Prepare Designs for High-Quality Results

Proper file preparation is key to achieving high-quality results.

- Resolution: Understanding DPI versus PPI and viewing distance is critical. A poster viewed up close needs ~300 PPI, while a distant billboard may only need 150 PPI or less. This also keeps file sizes manageable.

- Viewing Distance: A font must be legible from its intended viewing distance, whether that’s up close or from a highway.

- Color Space: Conversion from RGB (screen) to CMYK (print) is crucial. Colors can shift, so professional calibration and soft proofing are needed to preview the final output.

- File Formats: PDFs are reliable for embedding fonts and graphics. TIFFs are great for high-resolution photos, and EPS files are ideal for scalable vector graphics. For CAD drawings, use formats like DWG or PLT.

- Bleed and Trim Marks: Extend your background elements about 0.125 to 0.25 inches beyond the final trim line to prevent white edges after cutting.

- Vector vs. Raster Graphics: Vector graphics (logos) scale infinitely without quality loss. Raster graphics (photos) need sufficient resolution to avoid pixelation when enlarged.

Finishing Touches: Post-Print Processes

Finishing transforms a print into a professional, durable piece.

- Lamination: Adds a protective layer against scratches, moisture, and UV rays, which is essential for outdoor prints. It also adds structural integrity and comes in matte, gloss, or textured finishes.

- Mounting: Adheres flexible prints to rigid substrates like foam board or aluminum. This requires skill for a smooth, bubble-free finish.

- Contour Cutting: Uses specialized equipment to create custom shapes for logos, decals, or standees, moving beyond simple rectangles.

- Sewing and Grommeting: Adds durability to banners for outdoor use. Hemmed edges prevent tearing, and metal grommets provide reinforced mounting points.

- Professional Installation: This is often the final step. For large murals, sequence numbers on the margins guide installers for perfect alignment.

Conclusion: Your Partner in Big, Bold Printing

Understanding how large format printers work reveals their potential to transform your business. These machines combine precision engineering and creative power to turn digital ideas into stunning physical displays that command attention. The process is a fascinating blend of technology and artistry, bringing your biggest visions to life.

The power of large format visual communication is immense. From billboards to trade show displays, these prints deliver results that smaller formats can’t. They are durable, versatile, and offer an excellent ROI for businesses ready to think big.

At Associated Imaging Solutions, we understand that choosing the right printing solution is about finding a partner who gets your vision and has the expertise to make it happen. As your neighbors here in Philadelphia, we’ve been helping businesses across Pennsylvania – from the busy streets of King of Prussia to the historic charm of Lancaster, and from the innovation hubs of Pittsburgh to the growing communities in Altoona and York.

We combine the personal touch of local service with cutting-edge technology. Our team doesn’t just deliver equipment; we deliver peace of mind. Whether you need copier rentals, expert repairs, or comprehensive managed print services, we’re here to ensure your document management runs smoothly so you can focus on what you do best.

Ready to see what large format printing can do for your business? We’d love to show you the possibilities and help you find the perfect solution for your needs. Explore our range of Large Format Printers and find how we can help your business make a statement that’s impossible to ignore.